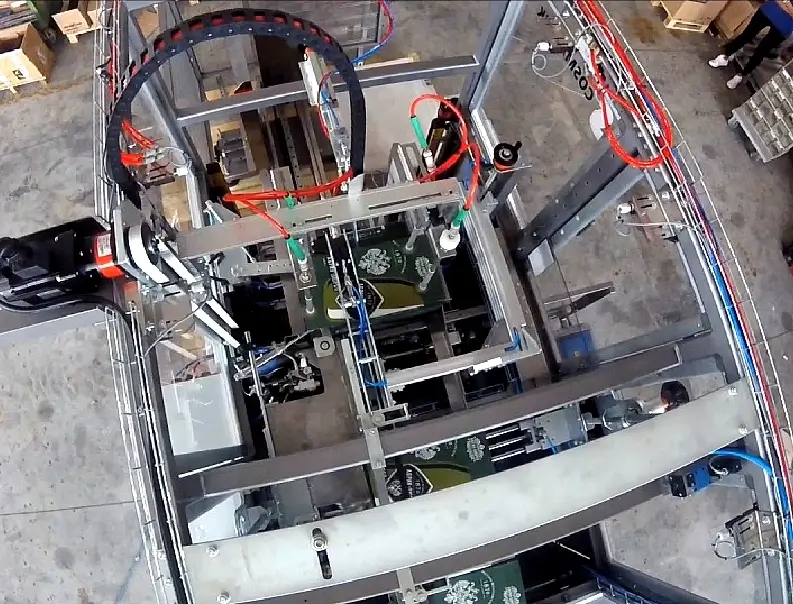

Case erectors are machines that have the scope of preparing the box for the cartoning process. Our long experience in box erecting allows us to prepare perfectly ereced boxes, even with poor cardboard quality. We build erectors of different speeds, up to 3000 boxes/hour. The bottom flaps of the box can be sealed with glue or with tape. Our range includes also tray formers, closed with hot melt.

Case Erectors

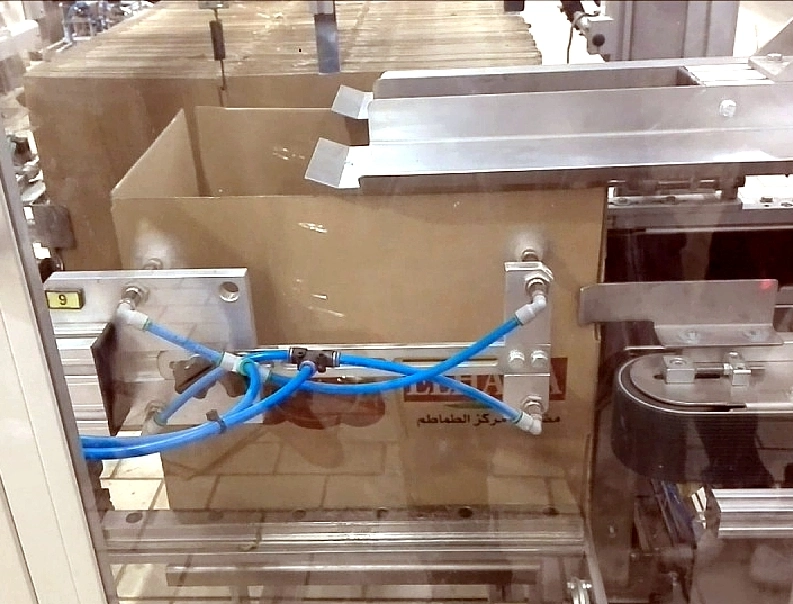

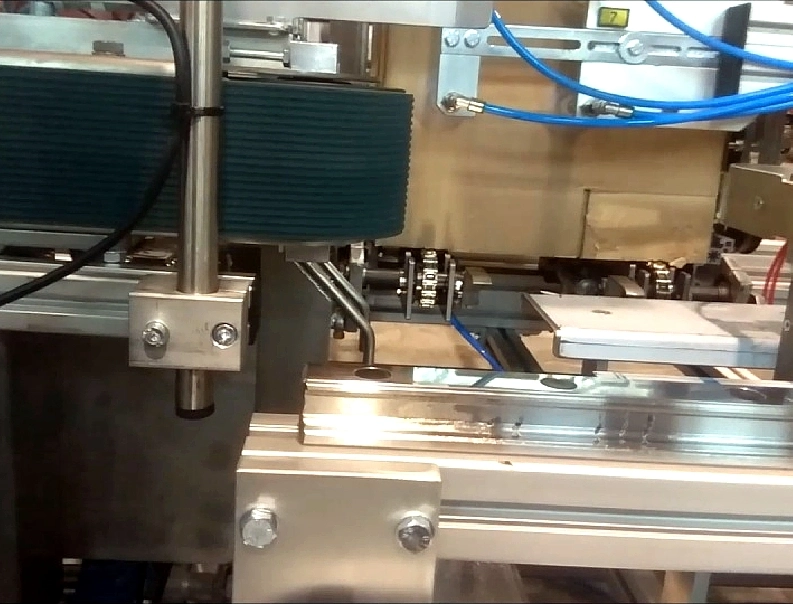

The case erectors machines allow you to create an american cardboard starting from a blank that is glued on one side only. The blanks are loaded into a magazine from which they are automatically picked up by the machine that will open them and close the lower flaps. The sealing can be with hot melt or with tape

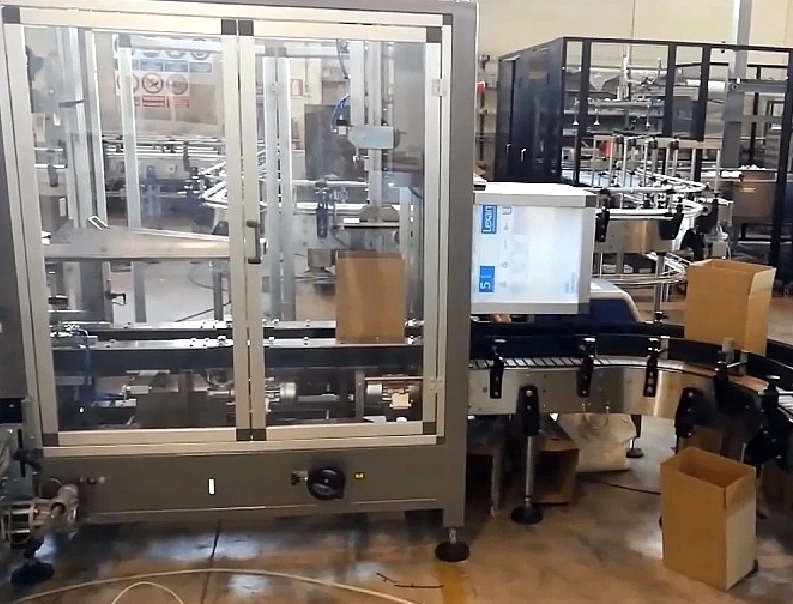

Up to 1200 boxes/hour

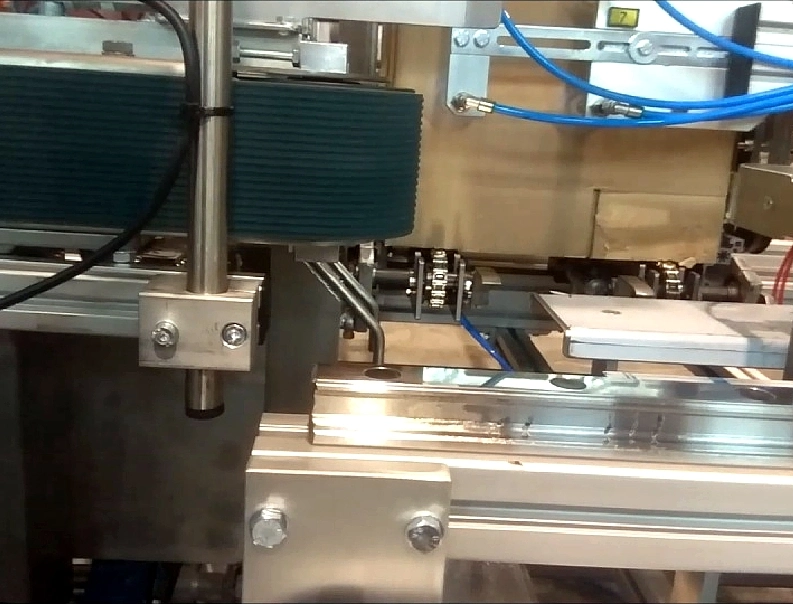

Case erector for medium productions. Small dimensions, high quality and versatility are the main points of strength of this case erector.

Can be equibbed with hot melt unit and also with taping unit to seal the bottom flaps.

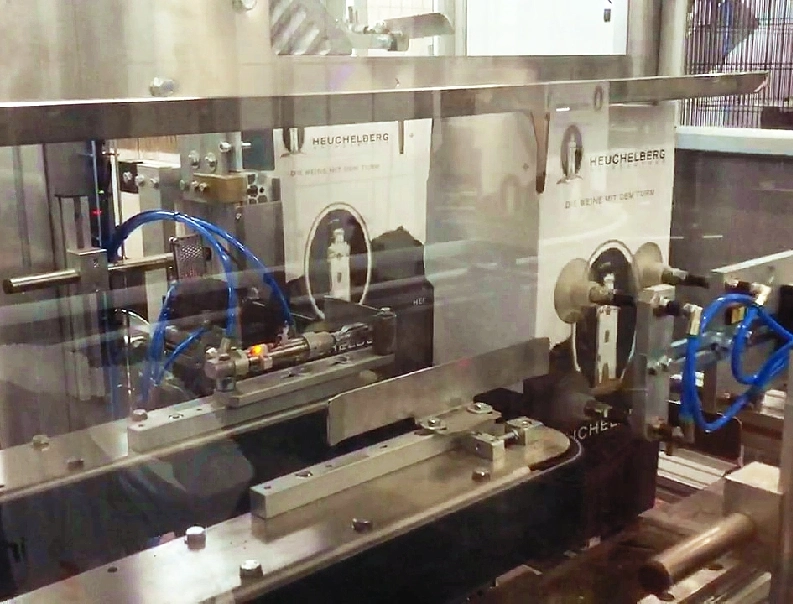

Case erector with glue sealing – speed 1000 cph

Case erector with glue sealing – speed 1000 cph

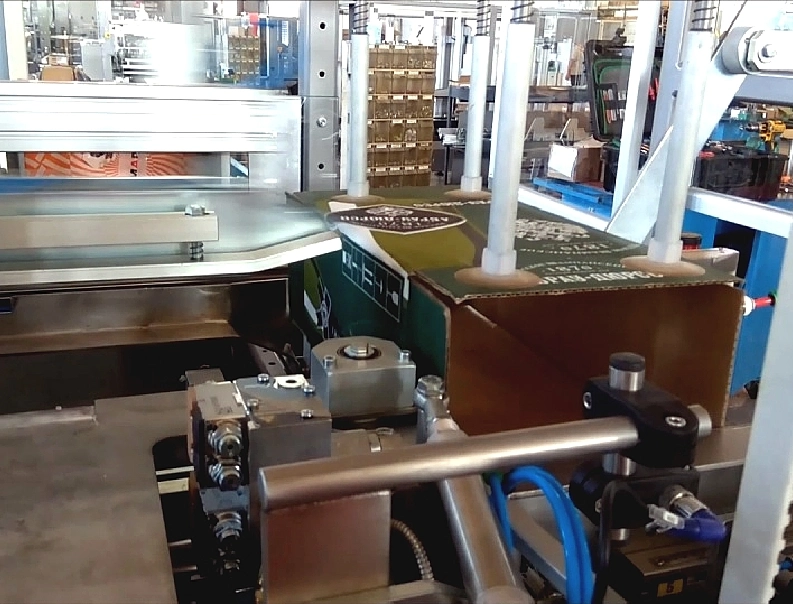

Up to 2000 boxes/hour

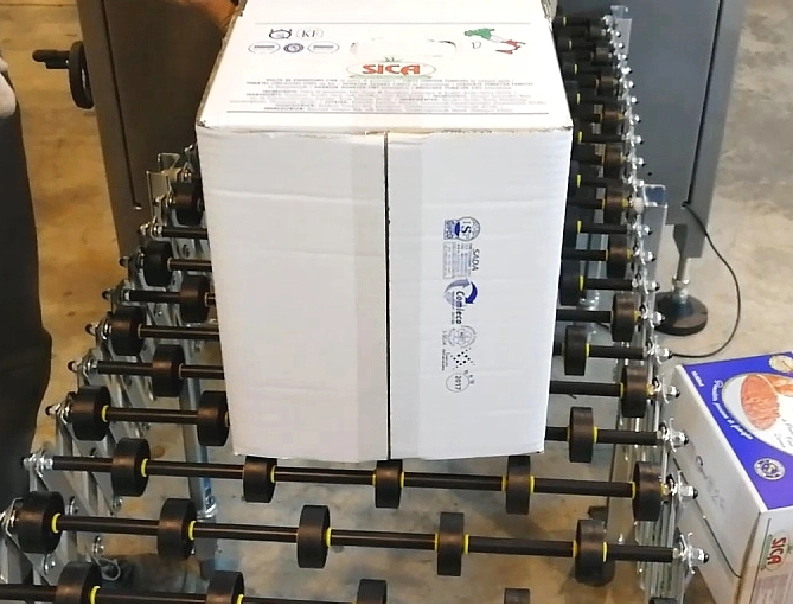

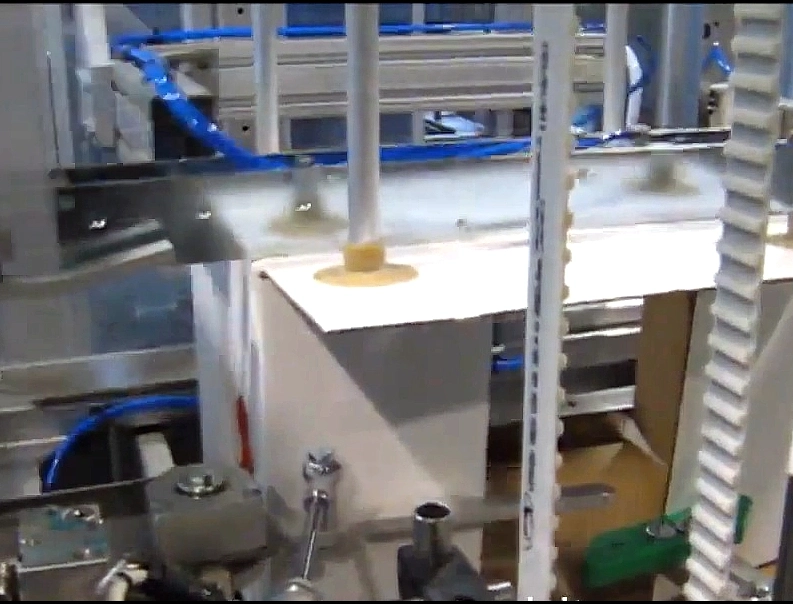

FOCA2000 is an american carton case erector machine. The carton will be closed in its bottom part with hot melt glue.

Case erector – speed 2000 cph

Case erector – 2000 cph speed – food processing sector

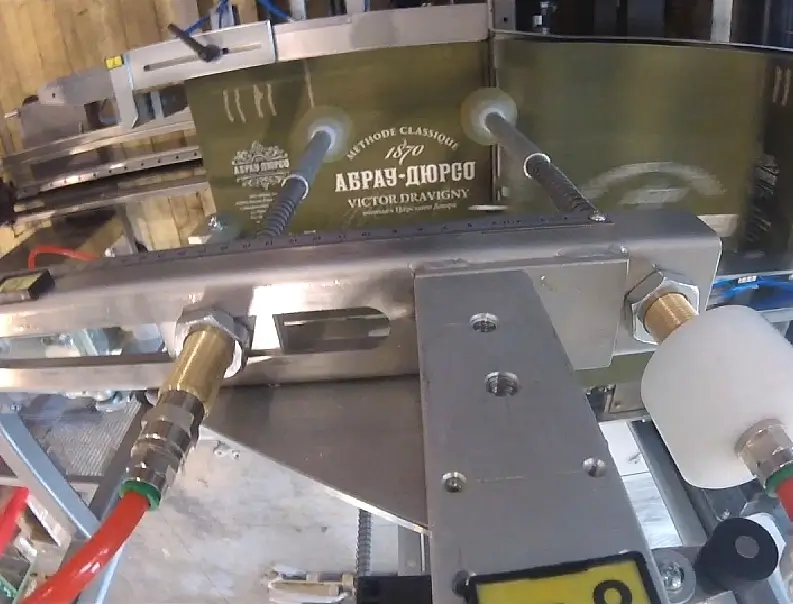

Tray Erectors

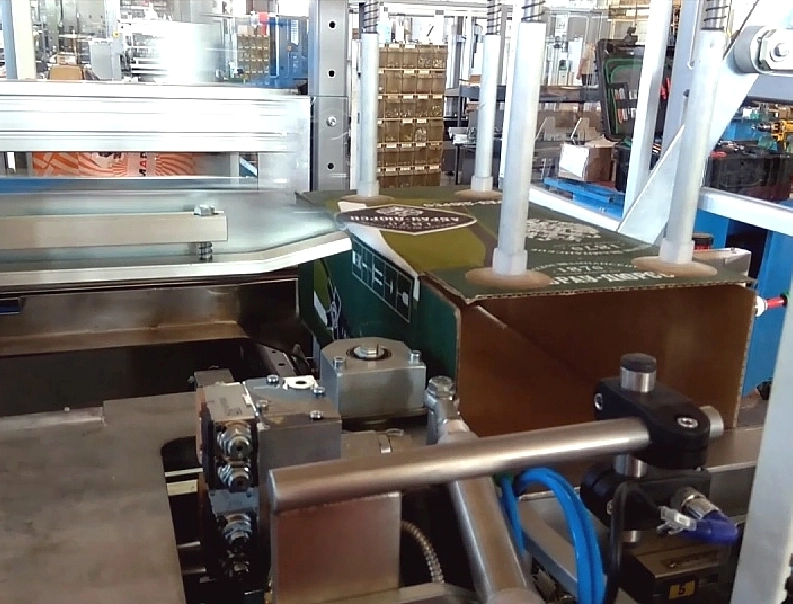

Tray forming machines are automatic machines which, starting from a flat blank, form the tray and seal it with hot glue.

Tray Erectors

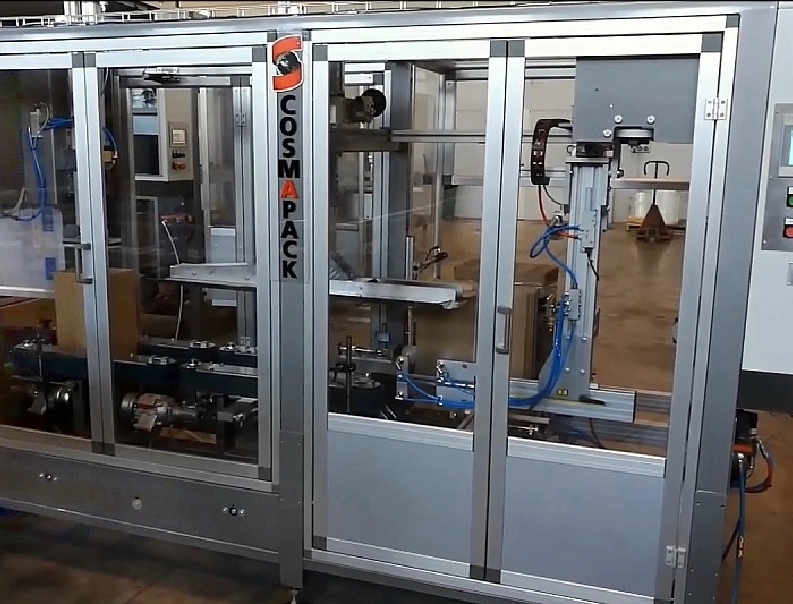

Tray erector for large dimensions FOVA 2000 is a tray erector able to process large trays with dimensions up to 1200×1000 (and higher). The flat cardboards are stored horizontally in a motorized tray magazine were the cardboards are lifted up to the pickup height. The cardboard is then transferred to the forming area. During the transfer glue tracks are applied in the proper position. When in the forming area the side walls are formed by pneumatically activated bars.