KPI Optimization & Continuous Improvement Services

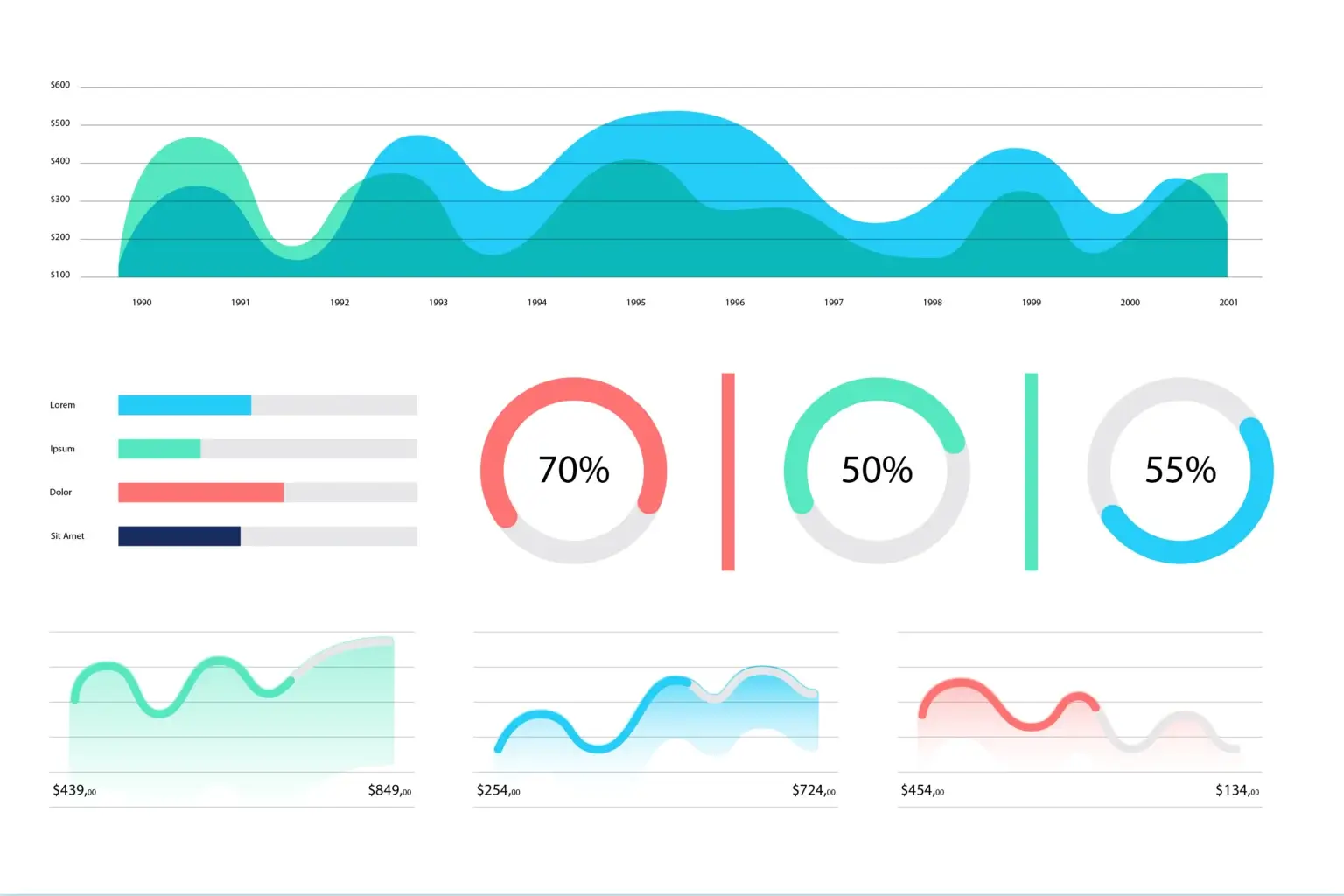

Unlock Peak Manufacturing Efficiency with Data-Driven Insights

At MOST Engineering Solutions, we help manufacturing facilities identify, set, and achieve key performance indicators (KPIs) that drive operational excellence. By thoroughly analyzing your plant’s capabilities and performance gaps, we uncover hidden opportunities to improve productivity, reduce inefficiencies, and enhance output quality.

Our strategic support goes beyond observation — we collaborate with your production and maintenance teams to implement measurable improvements that align with business goals.

Our KPI-Focused Services

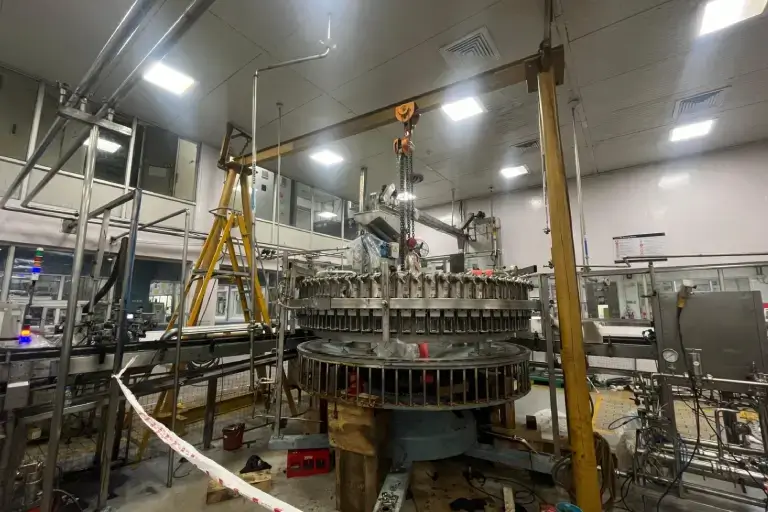

Overall Equipment Effectiveness (OEE) Monitoring

We evaluate your equipment’s availability, performance, and quality output to generate a complete picture of production efficiency. Our team identifies inefficiencies and implements strategies to improve machine uptime and throughput.

Availability & Performance Optimization

By minimizing unplanned downtime and process slowdowns, we help maximize your plant’s availability and performance ratios. We work closely with production leads to ensure machines are consistently running at optimal levels.

Capacity Utilization Analysis

Are you using your plant’s full potential? We analyze capacity vs. actual utilization to recommend solutions that help you meet growing demands without significant capital investment.

Rejection Rate Reduction

Our quality-focused audits and root cause analysis help identify product rejection trends. MOST provides corrective action plans to minimize defects and improve product reliability.

Advanced Support Services

Opportunity Analysis

We conduct a deep-dive assessment to identify underutilized assets, process bottlenecks, and potential improvements in your current workflow — all aimed at boosting efficiency and ROI.

Continuous Improvement Programs

MOST builds and implements custom continuous improvement frameworks (Kaizen/Lean principles) that empower your team to drive innovation and enhance operations every day.

Comprehensive Plant Auditing

Through structured plant audits, we evaluate the health of your operations — from equipment performance to workforce efficiency — delivering a clear roadmap for sustainable improvement.

Why Choose MOST?

- Holistic approach to KPI benchmarking and improvement

- Expert analysis of production floor dynamics

- Sustainable cost savings and output enhancement

- Actionable insights and easy-to-understand reports

- Onsite collaboration with your engineering and quality teams

Transform Your Manufacturing KPIs Today

Partner with MOST Engineering Solutions to uncover real improvement opportunities and achieve consistent production excellence.

Contact us today for a free KPI assessment consultation.