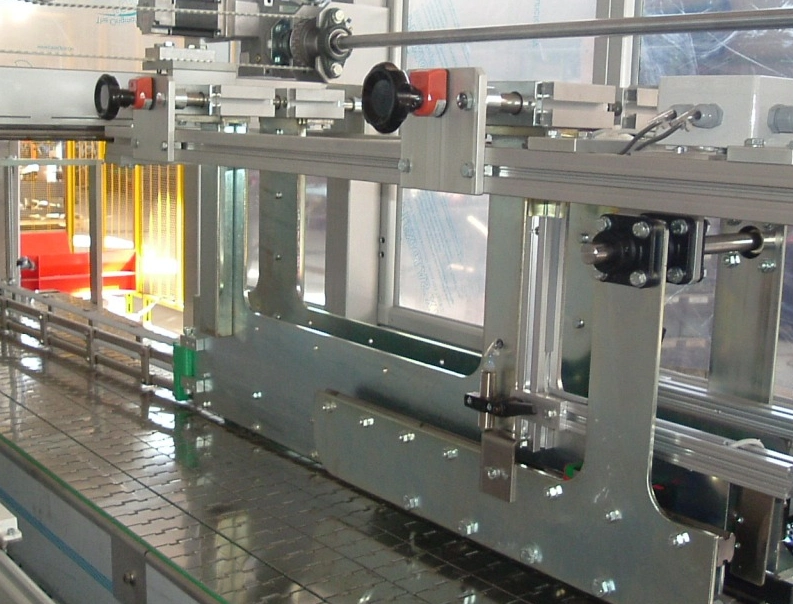

When the bottles are not round, the preparation of the layer to be transferred needs a dedicated machine that divides the flow of the product in multiple channels. We build dividers that allow continuos flow for fast production lines, or also intermittent flow for slower paces.

Interrupted Flow Deviders

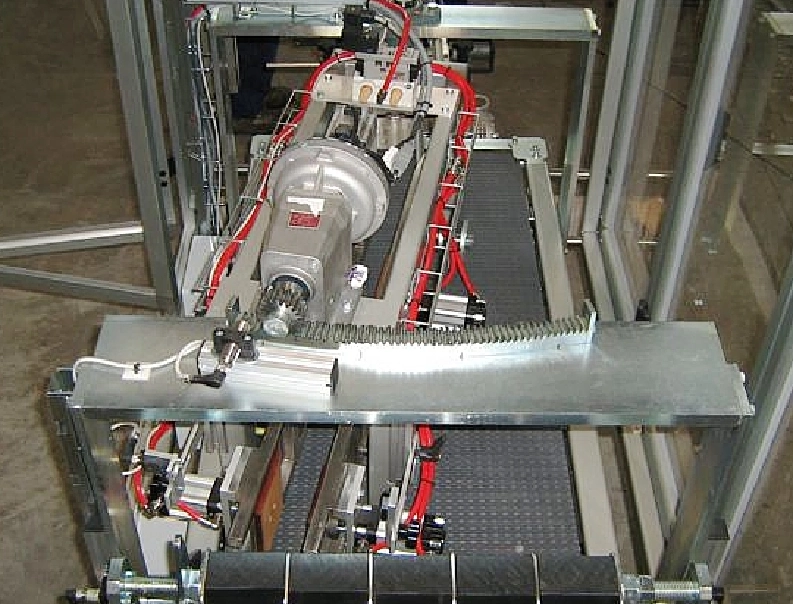

Devider for different products which come from one row and which get shunted on two or more rows. This devider is equipped with product stoppers that will interrupt the flow of the product while the devider is switching between the rows.

Bottle devider with alternating operation

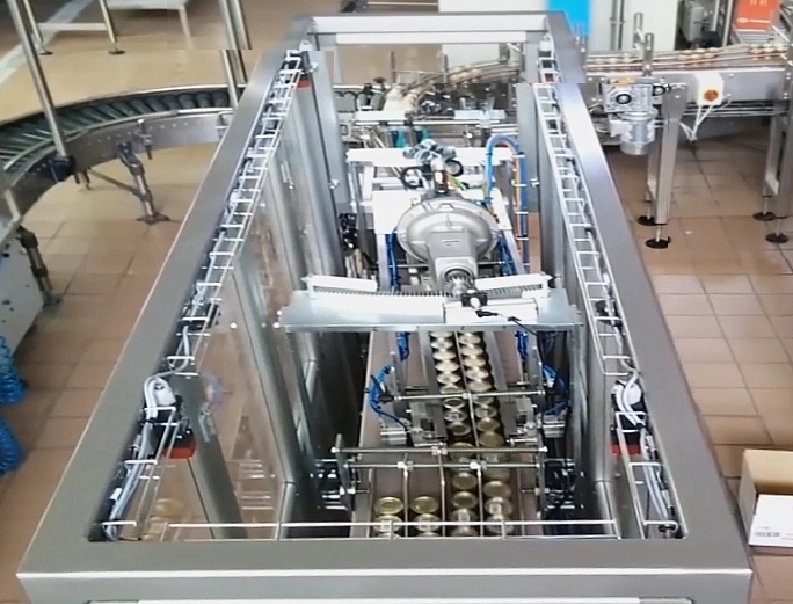

Continuous flow devider

The continuous diverters allow the product to be diverted without stopping the flow. Their main feature is the presence of a telescopic arm which, during the transversal translation, comes off accompanying the product and following it at the same speed of advancement of the belt.

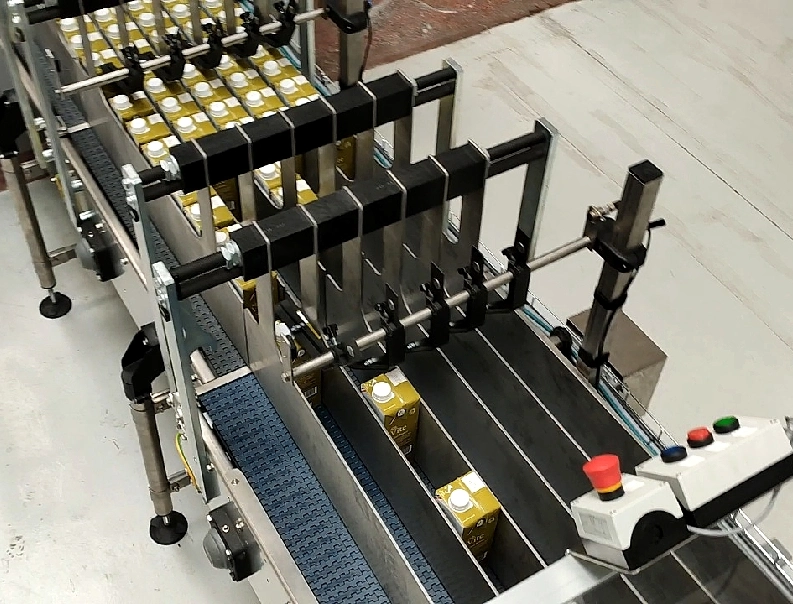

Continuous flow devider

The flow of the product is never stopped, but lined up through a telescopic device that provides a gentle allignement of the product on multiple lines. Besides its mechanical sturdiness, QUICKLINER’s point of strength is in its software: The speed of the product can be simply changed by turning a potentiometer. The machine automatically detects the new speed and adjusts the speed of the motors of the aligning device WITHOUT THE NEED of changing any other setting in the machine. The precision of the aligning system allows to devide properly even bottles that are touching one another. QUICKLINER can work with speeds up to 30’000 bph.